This page describes the neccessary glue code between the simulator and the optimizer and the changes made in the optimizer code. It contains:

controller file: setup of variable ranges and simulation setup, prepare the template file

DE-solver: generate populations, feed the cost function with test vectors

cost function: call all spice routines and return a cost value

* create spice input file out of the test vector and the prepared template file

* call spice simulator with that input file

* read the spice result file

* calcutale the cost of the test vector

Sometimes this is not allowed, for example infinite high capacitance values or stripline impedances larger than 377 Ohms. That's why either the DE solver or the cost-function needs to handle that case. Moving that boundary problem handling into the DE solver, it has to be written only once.

The newly introduced boundary modes are:

On the other hand, mode 2, 3 and 4 introduces new population members that are not really a result of the DE algorithm. They may disturb the original DE algorithm. Mode 5 is a compromise.

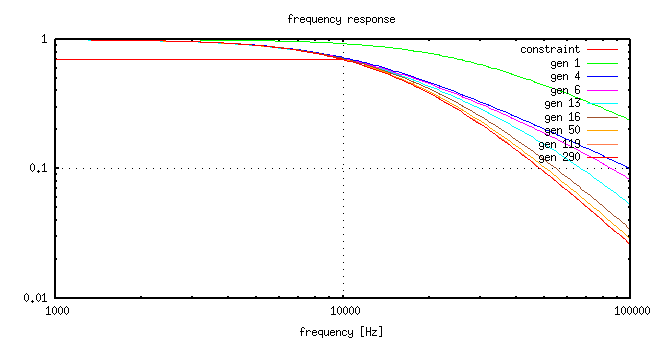

Below the cutoff frequency the signal level at the output has to be above 1/sqrt(2) = 0.707. This is the constraint for a lowpass filter. The cutoff frequency is defined inside the cost function. For every simulation point that violates that constraint I sum up a high penalty, e.g. 1 million.

Above the cutoff frequency there should be no signal. Well, no signal is not possible, but we can optimize the parameters to make the signal above the cutoff frequency as low as possible. As cost function I just sum up the amplitudes of the simulation values.

Note: As the constraint cost is much higher than the optimization cost, the optimizer will first fulfil the constraint and after that start the optimisation.

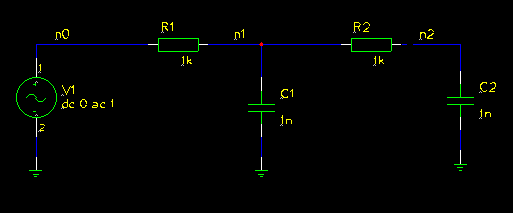

All part values have predefine value ranges. Usually nobody uses large capacitances or very small resistance values. That ranges are defined in the parameters structure.

If you have only two values to optimize you can use an XY-plot of the population parameters, too.

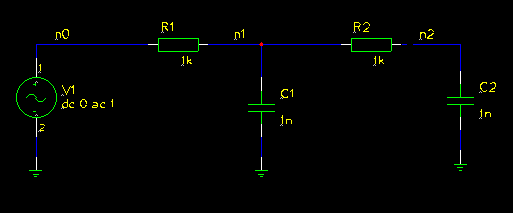

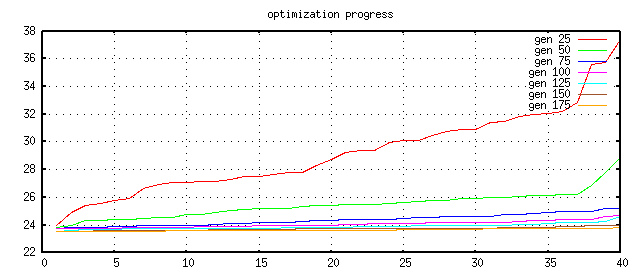

The following graph shows the cost after the first few parameter generations

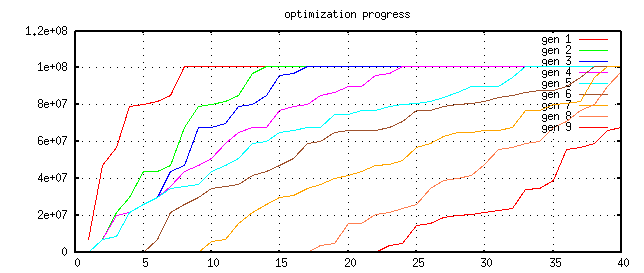

After the fifteens step, every parameter set fulfils the contraint function an the plot of the cost values rescales.

The cost graph becomes flatter and flatter. If the graph does not longer change very much, it's likely that the optimizer found a good parameter set for the problem.

After about 200 generations the result seems to be close at the optimum point.

Iteration=200, Best=2.353330e+01, cost_max=2.371315e+01, cust_sum=9.443513e+02 best(1)=1.000237e+03 [1.000003e+03, 1.111371e+03] best(2)=9.953464e+03 [9.284823e+03, 9.998692e+03] best(3)=1.040548e-08 [9.269194e-09, 1.107771e-08] best(4)=9.158298e-10 [8.664365e-10, 1.060045e-09]It is also possible to watch the progress using the frequency response graph.

The corresponding values to the graphs are:

gen. cost-value R1 value R2 value C1 value C2 value ------------------------------------------------------------------------- 1 5.662344e+01 2.804826e+03 5.016530e+03 2.012948e-10 7.849078e-10 4 3.201472e+01 9.894972e+03 3.881069e+03 1.368857e-09 1.505603e-10 6 3.068797e+01 5.292370e+03 4.089315e+03 2.561857e-09 3.286352e-10 13 2.823533e+01 1.245779e+03 1.496412e+03 9.375706e-09 2.347155e-09 16 2.584715e+01 2.162824e+03 9.980067e+03 5.568652e-09 5.877688e-10 50 2.432388e+01 1.043795e+03 5.612230e+03 9.591718e-09 1.509151e-09 119 2.360833e+01 1.005972e+03 9.710440e+03 1.047474e-08 9.197885e-10 290 2.352395e+01 1.000819e+03 9.997582e+03 1.021856e-08 9.290190e-10

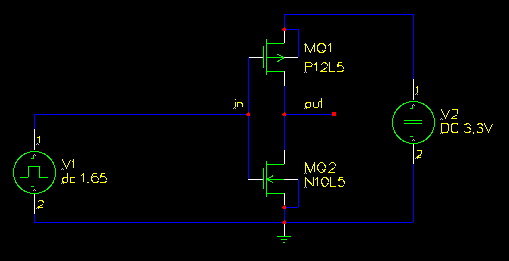

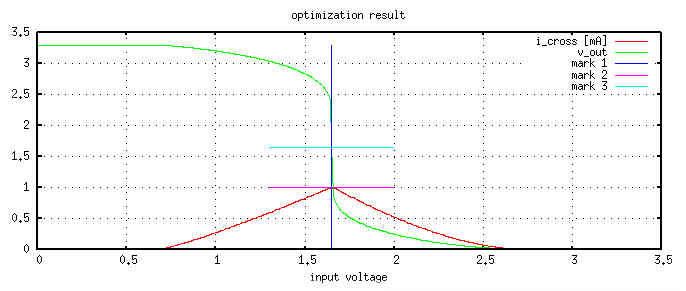

The result of the optimization looks like this:

The optimisation progress table of that run was:

The optimisation progress table of that run was:

gen. cost-value M1 length M1 width M2 length M2 width ------------------------------------------------------------------------- 2 3.716249e+00 1.510325e-06 7.798511e-05 2.073922e-06 4.611444e-04 2 1.408342e+00 4.322362e-06 8.861741e-05 1.917413e-06 1.569822e-04 3 3.771702e-01 8.795242e-06 2.642304e-04 2.499718e-06 3.134509e-04 7 2.084642e-01 2.452974e-06 5.018399e-05 4.700672e-06 4.917347e-04 28 1.971755e-01 2.154091e-06 5.045458e-05 1.774857e-06 1.653767e-04 88 1.617096e-01 9.720249e-06 2.863535e-04 3.053421e-06 3.982465e-04 144 1.564798e-01 3.668417e-06 9.669770e-05 1.561664e-06 1.476800e-04 199 1.082068e-01 9.836934e-06 2.305452e-04 3.946488e-06 4.306234e-04 214 1.043691e-01 6.950546e-06 1.795173e-04 3.856918e-06 4.637418e-04 232 5.164239e-02 6.356350e-06 1.613084e-04 3.870419e-06 4.622413e-04

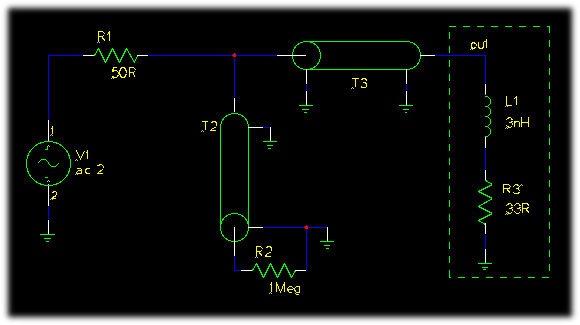

At that connection of R1, T2 and T3 the incident and reflected voltage are there. To get the reflected voltage the incident voltage has to be removed.

The reflection coefficient ist V_reflected/V_incident. As V_incident is 1V, the reflection coefficient is equal to V_reflected.

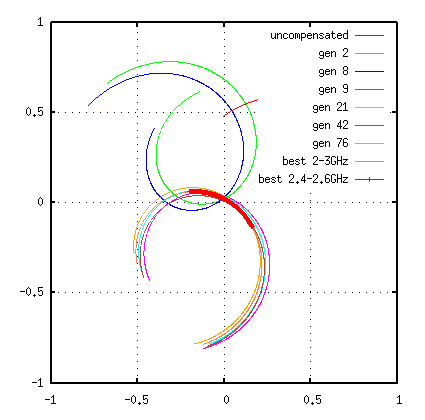

The next graph shows the reflection in the complex plain.

The optimisation progress table of that run was (some lines removed):

gen. cost-value T2 Z0 T3 Z0 T2 TD T3 TD ------------------------------------------------------------------------- 0 59.605 50 50 1e-12 1e-12 2 4.879770e+00 4.711152e+01 1.156916e+02 1.535854e-10 1.608469e-10 8 3.918364e+00 5.757418e+01 8.546133e+01 1.436777e-10 1.462799e-10 9 3.366191e+00 6.433881e+01 7.151574e+01 5.831321e-11 1.822875e-10 21 3.332348e+00 4.894428e+01 6.274242e+01 5.178099e-11 1.796019e-10 [...] 42 3.247336e+00 4.624785e+01 6.786233e+01 5.044231e-11 1.807375e-10 [...] 76 3.165438e+00 4.324340e+01 5.498546e+01 5.053047e-11 1.792231e-10 [...] 303 3.075487e+00 4.000000e+01 5.946972e+01 4.737848e-11 1.797402e-10